Want to know more?

Waste Pre-Processing for Co-Processing – AFR

Pre-processing is the art of changing waste into AFR.

Waste pre-processing for co-processing- AFR

We Manage Waste Resourcefully

About AFR

Though Co-Processing has gained momentum is recent decade, there are enormous financial, operational, regulatory and handling constraints attached to it. To overcome these limitations and converting most of the Industrial toxic wastes suitable for co-processing in Cement & other plants, Pre-Processing is an essential preparatory unit for final treatment & disposal through co-processing. It not only converts the waste to a usable form, but ensure consistent supply chain, uniform quality of waste and product, emission control, waste handling issues and legal non-compliances.

At Our Pre-Processing facility, we Provide a platform to prepare waste mix liquid/ solid from various wastes generated in industries to a “READILY USABLE AFR for CO-PROCESSING.

Solid & Semi-Solid Waste Preprocessing

- Pre-processing is the art of changing waste into AFR.

- Pre-processing can include Shredding, Segregation, Impregnation, and Foreign body removal.

- AFR needs a specialized handling system depending upon the fuel properties and variety of fuel to be handled.

- Equipment selection needs to be specific depending on the material’s physical & chemical characteristics, reliability, and maintainability.

Solid AFR Pre Processing: Plants & Machinery

Primary shredder(Trommel)

Magnetic Separator

Secondary Shredder

Blanding / Mixing Area (Blander)

Solid and Semi-Solid Waste Mixed Pre-Processing Facility to prepare fuel for co-processing

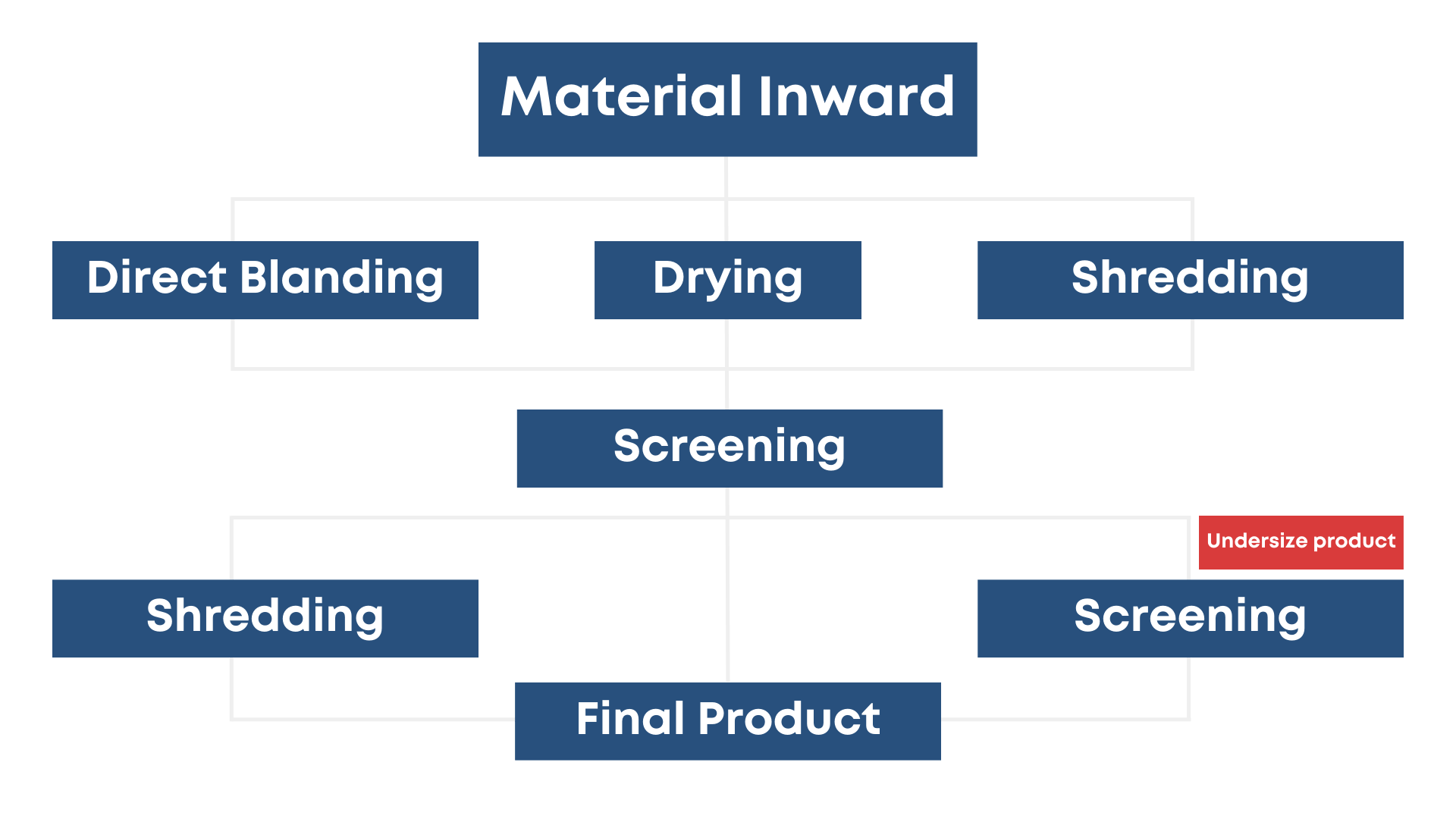

Process flow diagram

Brief Process Description

- Solid and Semi-Solid hazardous waste will be collected from different industries.

- A sample of all waste will be analyzed in the unit’s own Laboratory, and samples that are approved and compatible will be sent for further process.

- The moisture level of different solids and semi-solids will be maintained automatically, as some waste will be in dried condition and some will be in moist condition.

- Then waste will be sent to the shredder for size reduction.

- After that waste will be blended and mixed.

- The final product that has good Gross calorific value will be sent to cement industries for Co-processing.

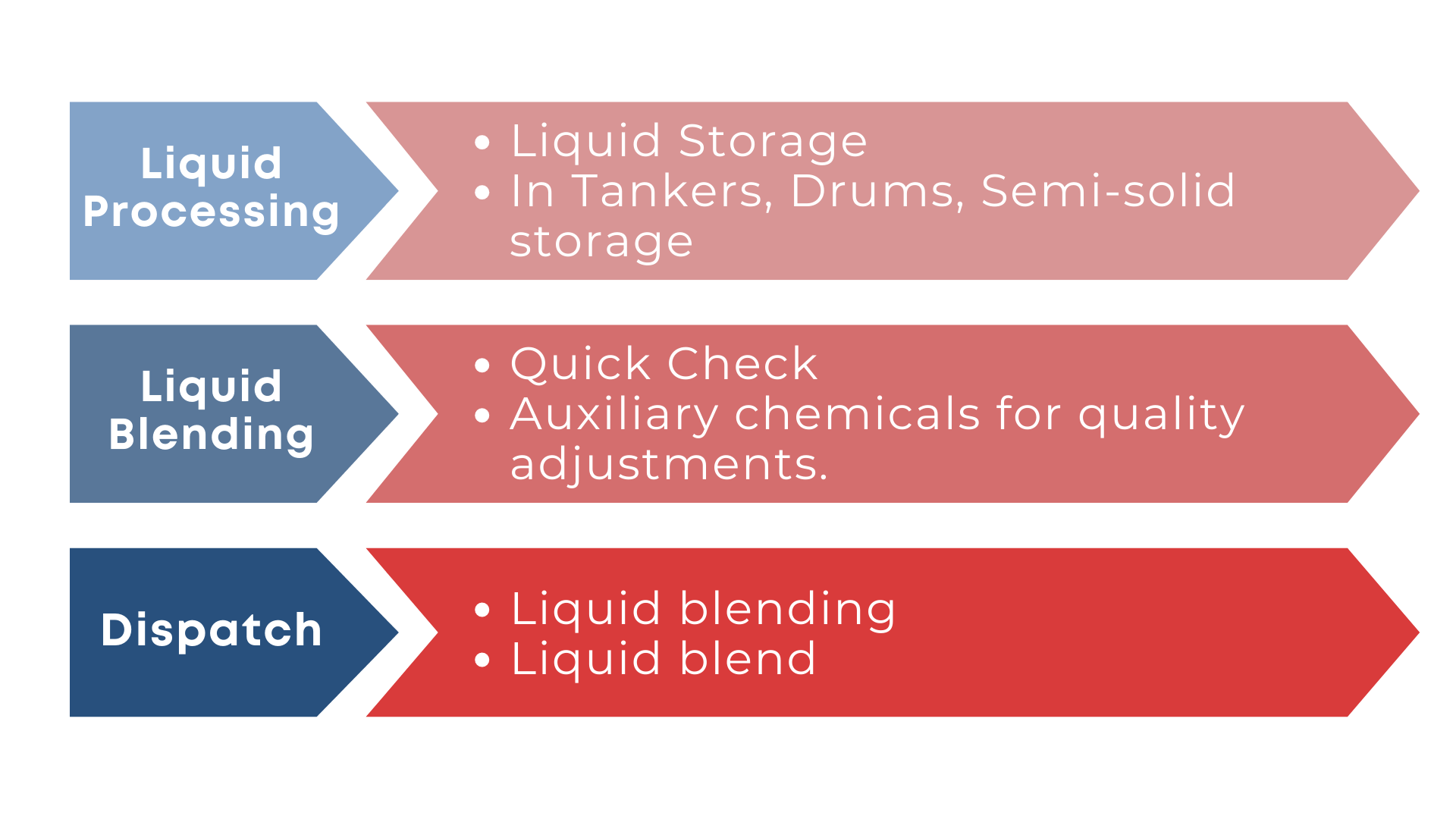

Liquid and Semi-Liquid Waste Mixed Pre-Processing Facility to prepare Fuel for Co-Processing

Process flow diagram

Brief Process Description

- Liquid and semi-liquid waste will be collected from different industries.

- A sample of all waste will be analyzed in unit’s own Laboratory, samples that are approved and compatible will be sent for further process.

- Then pH, Calorific value, compatibility, Density will be checked and then it will be transferred to the dedicated raw hazardous waste storage tanks.

- Then waste will be transferred to Mixing and blinding tanks to prepare a homogenous final material as per client requirements.

- Then sample sends for analysis to the in-house laboratory.

- The final product having good Gross calorific value will be sent to cement industries for Co-processing.

Get in touch

Got questions? Our expert team will answer all your questions.

Call Us

7486020970 | 6358911302

Hazardous waste generation is bound to upsurge with the “make in India” need. At Our Pre-Processing facility, we Provide a platform to prepare waste mix liquid/ solid from various wastes generated in industries to a “READILY USABLE AFR for CO-PROCESSING.

Open Hours

M-F: 8am - 6pm, S-S, 9am - 1pm

Contact Us

Office Location

Plot No. D/2/CH 378 to 380, GIDC Dahej II Road, Samatpor, Next to Lewens Lab Pvt. Ltd.Revenue Survey No. 237/P & 238/P Galenda, Taluka- Vagra, Bharuch – 392130 Gujarat State, India.